|

||||||

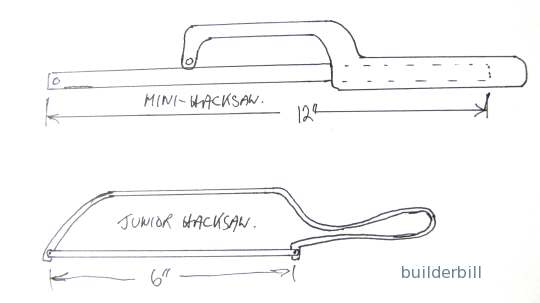

Graphical Construction Glossary >> Tools. >> Hand Tools >> Hacksaw TypesThere are three main hacksaw types

The hacksaw above is a standard 12" size. Some saw frames are adjustable for a number of blade lengths, with 10" being fairly common. In general the teeth are set facing forwards to cut on the forward stroke, however sometimes on thin material when using fine blades it it advisable to reverse the blade to cut on the pull stroke, similar to a coping saw, to prevent buckling the blade.

The old 19Th century hacksaw type on the right has a lot sturdier blade than the modern mass produced ones. It would probably have been used for cutting heavier material that today, would be cut with power tools. In fact the blade size and tooth pattern is very similar to modern power hacksaw blades. The power hacksaw itself is almost gone from the modern metalworking shop, being replaced by the faster band saws and circular cold saws.. Standard hacksaw frames using today's modern thin HSS (high speed steel) blades require a lot of tension to enable the saw to cut straight and on the push stroke without buckling. So choose a saw with a sturdy frame and a good method of tensioning the blade.

Smaller hacksaw typesThe Stanley Junior Hacksaw was an immediate success when it first came on the market. It's small size and cheap price made it a must have tool in many portable tool kits. The mini hacksaw frame uses the basic idea of a pad saw, a single handle supporting a thin blade. Because of the lack of rigidity of the blades the handle has an extension to support the blade. Fit the blade pointing toward the handle and cut on the pull stroke. This is a very slow and often tedious saw to use, but may times it is the only tool that will do the job. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. "What can be added to the happiness of a man who is in health, out of debt, and has a clear conscience? "When we build, let us think that we build for ever."John Ruskin 1819-1900 |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Glossary Pages.Roof Glossary and Roofing Formwork Glossary and other tempory work. Hand Tools Glossary Power Tools Glossary Asbestos Glossary Woodwork Glossary Stair Glossary Concrete Glossary Masonry Glossary doors Glossary BuilderBill Books Building Maths  Stair Design  Asbestos Book |

|||||

|

|

||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

||||||