|

||||||||||||||||

Ladders

Aluminium LaddersBy

far the most common ladders today are the extruded aluminium ladders. You can pick up used ones for a good price sometimes. You will be able to tell if it has been damaged. Timber Ladders.Still some of them around. In single form and extensions. They are made out of strong straight grained softwood, (spruce comes to mind?) They are ALWAYS clear finished. So that you can see any defects. Don't trust a timber ladder that has been painted for any reason. Wooden ladders tend to dry out and get loose as they go older. There are rods under the rungs, joining the two sides together. They are a bit like motor bike spokes, so I can't see any reason why they could not be tightened up and the ladder given fresh life. It is a very unsettling experience climbing a sloppy ladder. Apart from the normal in and out movement as you climb, they also sway side to side. Ladder Safety and Tips.It is rare that you just go up and down a ladder. You use it to do a job, so you could be carrying tools and materials up it. You could be on it and be sawing or drilling. You can apply many kilograms of thrust to the ladder, over and above your own weight when you are working on it, so you need a solid support. As far as I know ladder rungs are set at 1 foot apart. So an 18 pin (rung) ladder is 18ft long, plus a bit. A double 18 pin extension will get you safely onto a 28 ft high roof. Say four rungs overlap at the join, three rungs over the top and a foot or so for the slope.

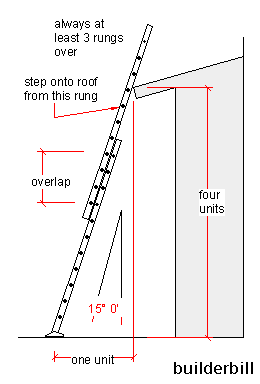

On the right is a sketch of an extension ladder leaning on a roof edge. The angle of the ladder to the vertical is important. Four to one is the recommended angle ratio. Note! In nearly 50 years up and down ladders I have never done any sort of measurement for this. Always I've done it by eye and what feels right. Having said that, when I was taking the photo below, earlier today I decided to set the ladder at 4:1 ratio and straight away it felt too steep for me. I needed a bit more out from the wall to feel comfortable. Just my opinion, but you have to work with what feels right. If you have it too steep, as you are climbing up it the top tends to skitter about or feel loose. There is not enough weight resting on the roof edge. If you place it with too much angle, the bottom is liable to slide out, but more importantly you are making the ladder itself carry too much of your weight instead of the ground. Also you will be leaning at an unnatural angle as you climb.

The older I get the more convinced I am that some jobs should never be done when you are alone. I am not saying that you may need a helping hand to do the work. What I am saying is just to know that there is someone nearby to call in case of emergency. Working on ladders, particularly high ladders is one of them. I went onto a house job about

four years ago and there was a young guy sitting in the shade. He looked sick and he

was grey, still suffering from shock. Raising and Handling LaddersStraight away the term "foot it" or "footing a ladder" comes to mind. You are about to raise a 30 ft. ladder. You say to your offsider, "foot this for me mate". You go to the top end. He gets at the bottom or foot and puts his boots onto it holding it firmly to the ground. You lift up your end above your head and walk towards your mate hand over hand on each successive rung, as it gets higher your mate grips the sides and pulls up also. When it is vertical you both maneuver it into position. You may not have an assistant handy, so you push the foot into a wall, a pole (not electrical), anything quite solid that will stop the ladder kicking up when you get past half way. Once you have it vertical you have one hand low down on a rung and one as high as you can reach and just lift it a touch off the ground and walk with it to where you want it. If it starts to lean, rest it down and steady it before moving again. Dropping it is the reverse procedure. A small extension you can handle one man, lift it and extend it with the ropes no worries. For large extensions, extend it first then lift as normal. If you land on the roof but need it a bit higher, a pull on the ropes will take it up a couple more rungs or so. Make sure that the hooks on the top part of the extension are properly locked into place before you start using the ladder. If you are short of room to raise the fully extended ladder, raise it in it's compact form and extend it when you have it vertical, with one man holding the ladder and one pulling the ropes. Electrical safety ladders.These are usually made out of fiberglass, but some are still made out of timber, for their non conductive properties. A variation they sometimes have is a rope instead of the top rung, so that the ladder can rest against a round pole safely. Cat Ladders

These are ladders for working on steeply sloped roofs. All the ones I have seen have been home made and out of fairly flimsy timber. Say 3" x1" sides and 2" x 1" rungs. About the same width as an ordinary ladder. Sometimes the joints are housed in, sometimes just screwed. They don't have to be very strong, as they are only designed to stop you sliding off the roof when working on it. The roof itself provides the support. Say if I had to fix a skylight in a roof that was over 20 or 25 degrees, I would probably make up two of them. one on either side of the work area. They would give me a secure footing while doing the work. I could hook my tool bucket onto a rung and also lodge the materials on them. Step Ladders

Always extend step ladders to their full width, so that the folding struts are fully extended and allowed to drop slightly into their locked position. Again these are mostly extruded aluminium, with a very wide range of qualities. Some of them unfold into an ordinary ladder, but so far I have not seen one of these combination things than I would be happy working on. A couple of the steel ones I have seen were quite robust. Apart from just plain strength, these double sided ones give a lot more range for the one ladder position, so if I am painting (cutting in) around a ceiling, I go up one side and reach to paint 4 or 5 ft. then step over the top and reach an extra 4 ft or so. The small three step ladder is my favourite, I use it for heaps of small jobs around the house. The taller one is a replacement for a similar one that I had for years. It got stolen so I replaced it with exactly the same ladder. "When I were a Lad"When I was about sixteen, I spent three days footing a ladder in the center of the town I lived in. I was protecting the bottom of the ladder, making sure that no body tried to climb it, interfered with it or bumped it with their car. I was there to steady it when the other guys were using it.It was access to the roof of a building that was at least three stories high, but it could have been four. The ladder was huge. What we called a pole ladder. If you imagine a round piece of timber, tapered from say 8 inches at the bottom to say 4 inches at the top, then sawn in half length ways, that was the two sides. It was about 2' 6" wide at the bottom and about a foot at the top. I saw a plumber carry a roll of lead up this ladder and it took on a curve that was just about vertical at the top few feet. We had the foot resting in the roadway, with the footpath unobstructed to provide access to the shop. About 90% of people chose to walk into the street around the ladder, rather than go under it. The old superstition of it being bad luck to walk under a ladder was alive and well in those days. The old pole ladders were really good to work on, (once you got them in position of course), but some of the other ladders we had to work on were a different story. We had triple extension ladders in timber that were nearly as tall as the largest pole ladders. Because extension ladders need to have parallel sides they weren't half as stiff as the old pole ladders. I have never seen it happen, but it was not uncommon for an old sloppy extension ladder to turn inside out when someone was climbing it. That is the top and the bottom stay firmly in place, but the middle with the guy on it swings through 180 deg. and he finishes up on the inside of the ladder. Ah..... who wants to bring back the good old days. Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Quick Illustrated Roofing Glossary Pages.Types of roofsRoof Features Roof Framing Roof Trusses Roof Coverings In Depth Roofing Articles

|

|||||||||||||||

|

|

||||||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

||||||||||||||||