|

|||||||||||||

Low tech Solutions

I am a great one for using low-tech. solutions to problems. Quite often I see jobs where people are getting carried away and buying or hiring expensive gear to do one off jobs. Steel Acrow props come to mind, when a timber prop and fox wedges would do the job. If you have seen any of my roofing pages you will know that I advocate the use of drawing to get answers to roofing problems. What could be more low-tech than a piece of paper or ply, a pencil, a square and a ruler. All over the world people for centuries have been building beautiful and complex buildings with very basic tools. When there was no high-tech, everything was low-tech. Yet now our kids seem to be lost without the latest hi-tech gadget. Low tech - "Fox Wedges" or Folding Wedges. Wedges in Pairs.A wedge is a simple machine. It is a relative of that most simple of

mechanical devices, the inclined plane.

When

two timber wedges of the same slope are used as a pair, they become a

whole lot more useful. We used to call them "fox wedges" or "folding

wedges".

Low tech -Box Crib, Two Men, One Demountable Building, No Crane, No Problems. Or, Young Henry and Lateral Thinking

One of the best examples of using a low tech solution to a problem that I have ever seen, was many years ago at Wattie Creek (Daguragu). Young Henry (we called him Young Henry 'cos he was younger than us when we first knew him as an apprentice. He's in his 50's now but he's still called Young Henry:-), bowls up on the job in a small truck and proceeds to put in the foundations for a 12m x 3.5m demountable health clinic. Seeing as we were a few hundred kilometers from home (600km SW Darwin) I asked him how much it was costing for crane hire. "Nothing" he said. "Don't need one". Sure enough he didn't. With the timber he had in the back of his small truck, and help from the truckie, he used a simple machine to lift the fairly large building off the semi and position it correctly on his foundations. The simple machine that Henry used was a lever. I would like to say that he used a 3M. length of sturdy timber, which he certainly could have done.What he actually used was a high lift jack, (kangaroo jack) that is just about a standard piece of equipment with 4WD vehicles. The jack is itself another example of a lever in a more compact form and another low-tech tool. It made his job easier, but he could have done it with a length of timber. Another

key item in the job was what we used to call a pigsty. Known more correctly as a box crib. Here's how he lifted the demountable building off the semi-trailer and onto his foundations. I have no doubt that the company that made the buildings designed them and the foundations to be able to unload them in this way. Henry didn't invent it and neither did the engineers at the company he was sub-contracting to. This method of raising heavy weights must have it's origins in pre-history.

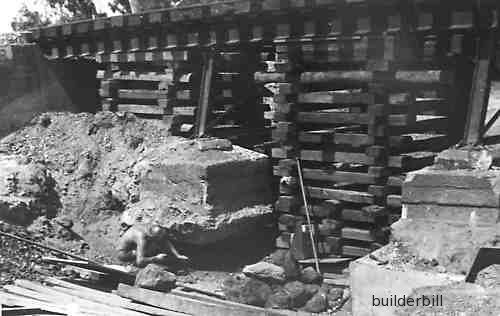

Easy peasy, it took two men about 4 hours to do the job. It would have taken a truck mounted crane only half an hour, obviously more economical, but then add the cost of say 12 hrs traveling time. Another example of Young Henry's lateral thinking. We were at a party one night at nearby Top Springs, cops, nurses, schoolteachers etc. Word came in that there had been an accident on the Buchanan Highway, so just about everybody raced down to the scene. A guy had run into some cattle, killed one, wrote off his car, but luckily was not too badly injured himself. Henry takes in the situation, cops and nurses have it all under control, so he gets his gear out of the truck, sharpens his knives and to much outrage from the females present, proceeds to butcher the beast, (as you do). We had fillet steak stews for a while after that. It's a tough job working out bush, but somebody's gotta do it. Low tech - Underpinning Railway Bridges.Henry's use of the stacks of lightweight timber to support the demountable building didn't surprise me all that much, as I had been introduced to the structure a couple of years previously when I underpinned the foundations on three railway bridges on the North Australian Railway. I had to support a bridge while we excavated under the concrete foundations and formed up and poured deeper and wider concrete supports. We had to at certain times allow loaded, sometimes triple header (3 engines), iron ore trains to pass over. How much do you reckon it cost me for the props-support structure to do this? (Yeah I know, you've looked at the photo already and worked out the answer that it cost me stuff all).

As you can see what we used was discarded timber railway sleepers that we found alongside the track. We put smaller timbers and fox wedges at the top to take up the slack. This method was common with the guys working on the railway, and they called them "Pigsties" which as far as I know is just a local term. Incidentally, in these days of mobile phones, it seems ludicrous now our method of communicating with the railway headquarters in Darwin. There was a telephone line running alongside the railway line. We had a small polished mahogany box with a couple of brass terminals on it and a rotating handle. We had a bamboo pole with wires on it that hooked over a pair of wires onto the telephone line. When connected to the box a couple of turns on the handle resulted in a connection to Darwin. Over a hundred years after the Overland Telegraph was built in this area, we were still using similar technology. The last time I used a pigsty was only a couple of years ago. We built on site a large concrete wash trough for a laundry. No problems forming and pouring, but at about 150 kilo how to get it into the laundry and then lift it into position and hold it there while we bricked it in. Rollers (short lengths of steel pipe) and levers got it in there, and a 150 x 50 x 3000 hardwood lever lifted in up in increments of 50 on a pigsty we made out of scrap timber around the job. Leave low tech and back to home page.Low-Tech To Do ListLater I will be adding more low-tech items to this page, keep in touch.Low tech or safe manual ways of moving heavy objects, RHS steel, sheets of ply Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship |

||||||||||||

|

|

|||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||||