|

|||||||||||||

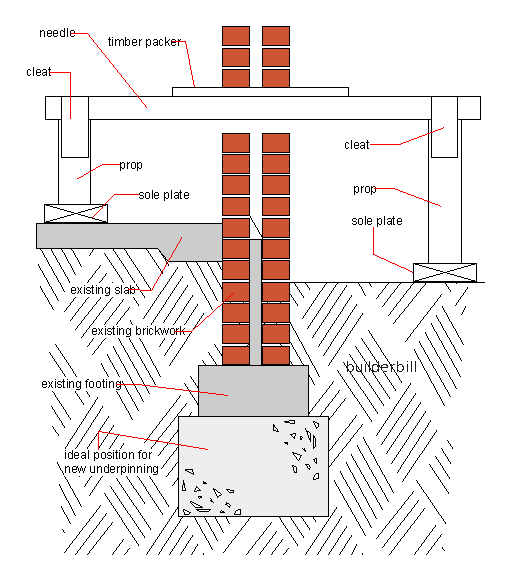

brick underpinning or repairs to brickwork wall foundations.Underpinning the concrete foundations of brickwork walls. Brick underpinning for short..

Bored or drilled, cast in-situ concrete piles

This modern method of brick underpinning is obviously less intrusive and safer than the older methods that follow. It has the possibility of being able to lift the building somewhat, thus maybe closing up the cracks, leveling doors and window heads etc. The piers are typically two to three metres deep. The spacing of the piers is determined by the structural engineer

Traditional method, supporting a brickwork wall.

What follows are details of brick underpinning a wall by older methods. You may ask why bother when newer methods are better? Well you may not have modern machinery available, or you may not have enough access for a machine. It could be an internal wall that needs brick underpinning. We need to take the weight off the wall, to support it in another way while the underpinning work is being done. The sketch above shows an old way of doing this, using timber. The same principle applies when using steel props and needles.

Traditional method, excavation and pouring.

I can't think of any circumstance that would allow anyone to try underpinning the full length of a wall, and then pour the concrete in one hit. The work has to be done in sections. Once again it is a compromise between time and cost on the job, offset against safety. A practice that I have applied to dozens of situations when doing contracting work is to run through the "best case - worst case" scenario. For a job like this I think on these lines.

So here I can't say how far apart to do each section, whether to prop or not prop, etc. Each job is different, but safety should always be the main concern. Partial Underpinning a foundation.

In certain case this could work very well, it is easier to do and a lot safer than the previous method. It all depends on the job. Other methods of underpinning are in my new glossary section. Leave this brick underpinning page and back to home.. Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Other foundation related Pages.

|

||||||||||||

|

|

|||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||||