|

||||||||||||||||||||

Graphical Construction Glossary >> Woodwork. >> Power Tools >> Power Saw

In spite of the fact that the saw below looks antiquated and should be on the scrap heap after many years of hard work (tell me about it :-) it will be good enough to illustrate what a sidewinder type of saw is. It is fitted with a TCT blade that is used for general cross-cutting.

I must have had quite a few of these saws in my time but the four remaining (two 160mm and two 225mm) have more than paid for themselves. The fact that they are still in good condition after catching heaps of abuse and misuse is a testament to modern power tools manufacturers. So... if I was in the market for another saw like the one above then these are the sort of specs that I might see. (From Makita website)

So a couple of facts to take away from the above stats:-

These saws particularly in the 225mm size can give quite a kickback if they jam, so they are mostly held with both hands.

The base of all of these power saws can be adjusted to control the depth of cut. At the front is a pivot point and at the rear is a wing-nut which grips on a curved slide. By lifting the base up and down the depth of the blade showing can be measured. Here is one of my smaller saws and below is a shot of another saw set-up in a similar way. It is cutting through a 20mm piece of material. For best running I recommend that the the saw blade should cut through and have about 10 or 15mm showing below the cut.

So at the back of the baseplate there is the curved support that allows for depth of cut adjustment. At the front of the base is another curved support that allows the angle that the blade makes with the blade to be adjusted. The saw shown here all all set to making square or right angle cuts, but it is possible with all these saws to cut at least 45 degrees and sometimes up to 50 degrees. The photo above does not show the angle adjustment at the front really well, but look at the last photo below on the right and you will see it clearly.

One of the most important items on these power saws is the blade guard. It is spring loaded and it should always return to closed as soon as it is taken away from the work. It is common to give it a few flicks with the handle before the machine is used for the first time to check that it is running freely. In the photo above the saw is just being started in the cut and the blade guard is pushing against the edge of the work. As the saw advances it will move upwards.

Above is a photo of a Hypoid Saw. It is claimed that they are more convenient and easy to use than the sidewinder and that they deliver more power. In the photo you can see that the grip is behind the saw and all the thrust is in the direction of the cut. With a sidewinder the grip is more above the saw with part of the thrust being downwards. I used to own a Makita Hypoid for about a year I guess until it got stolen off a work site. In the time I owned it, it got plenty of work and I would say that for working on a bench sawing up sheets of ply etc. it was very good, did an excellent job. For working on a roof, sawing roof battens and rafters I found that the handle was too far back and it was just a lot harder to use single handed. When to saw got stolen I didn't bother to replace it.

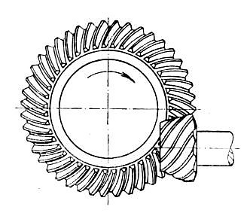

Hypoid Bevel Gears are made on a curved line and they mesh over a longer distance giving a stronger joining surface than a straight gear. This leads to longer life. At the right is the front view and as mentioned earlier it clearly shows the wing nut and curved support for altering the base/blade angle. If you didn't find exactly what you are looking for try this search tool that will search the site and the web. "What can be added to the happiness of a man who is in health, out of debt, and has a clear conscience? "When we build, let us think that we build for ever."John Ruskin 1819-1900 |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Glossary Pages.Roof Glossary and Roofing Formwork Glossary and other tempory work. Hand Tools Glossary Power Tools Glossary Asbestos Glossary Woodwork Glossary Stair Glossary Concrete Glossary Masonry Glossary doors Glossary BuilderBill Books Building Maths  Stair Design  Asbestos Book |

|||||||||||||||||||

|

|

||||||||||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

||||||||||||||||||||