|

|||||||||||||||||||||||||||||

Bathroom Renovation, Page TwoPatching the Bathroom Walls With Cement RenderThe surface that ceramic tiles are to be fixed to should be clean and straight with no loose material. It is pointless spending a lot of time and money on a bathroom renovation if the second most important thing is not done well. Ah you are saying to yourself, if the tiles are the second most important thing in a bathroom job, what's the first? I believe that the most import thing I did when I renovated my bathroom, was to do a good waterproofing job, and to get it inspected and approved before I covered it up with ceramic tiles. The parts of the walls that had a textured paint finish on them had to be scraped back of loose paint, because I was now going to tile the whole of the bathroom, not just around the bath. They came clean fairly easily. A 50mm wide paint scraper got under the paint layer and it came off fairly easily. The walls that had been tiled were a bit rough, some patches had rock hard tile adhesive still on them and in others parts the tile and adhesive came off together. I tried grinding off the hard glue with my angle grinder but it was not really successful. I wasn't taking much of the old glue off because it was so hard. Yet at the same time when I over ran a bit, I was digging into the parts that had no glue, so I gave it away and decided to plaster up to the level of the old glue.

So mixing up some plaster as described on the previous page I primed and plastered the wall patches that needed it. I laid the stuff on thicker than necessary and leveled it roughly, and then left it for a couple of hours. When it was quite hard, I used an aluminium screed to sort of scrape off the excess and bring it to a reasonable surface. Picking the right time to scrape it back is a bit tricky. If you try too soon you are basically doing what a tradesman plasterer does, and that takes a lot of skill. More than I have anyway. With the bathroom tiles going on later to cover up my patchy work, I was fairly confident that I could get it good enough. Preparing The Old Floor For The New Cement Topping, ScabblingAfter the touch up plastering the next job was to clean up the floor and lay a bed of sand and cement topping. A quick scrape around with a shovel removed most of the rubbish on the floor and it was looking quite clean. Of course this quite clean floor was what the existing topping was laid on, and that one was drummy, it was not bonded properly. I needed to scabble the floor. That is to get the old floor into a state where the new sand and cement topping will bond onto it.

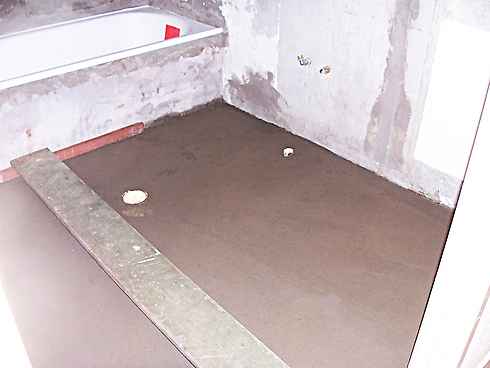

So I bit the bullet, put on my ear muffs, dust mask and visor and gave the floor a good run over with the diamond grinder. Cement Topping, Falls To Floor Waste

When I scraped it off, the topping was still not hard enough to walk on, so I had to put a plank across to work off. The end of the plank against the bath had a bit of timber nailed to it to keep it above the surface. That rested on my first laid 20mm thick strip which by this time was hard enough.

The following morning I couldn't resist trying it with a hose on the new bathroom floor to check the falls. I also tried the surface for straight and found a small bump (under my plank area) which I rubbed off with a half brick and water.

Waterproofing Wet Area WallsThe BCA requires that all new wet areas, that is kitchen splash back, laundry, WC and bathroom be waterproofed with an approved system, prior to the fixing of ceramic tiles. On new houses inspections are required before proceeding with the ceramic tiling. Otherwise excellent bathroom work has in the past failed the test of time, due to building movement. Different rates of movement between the bathroom floors and walls. Sometimes the internal walls are a different construction to the external bathroom walls. There are many different kits for doing the job. I got my waterproofing and tiles from a shop that imports quality tiles from Italy and Europe, and I went with the Mapei (Italian manufacturer) system, for both the waterproofing and the tile adhesive. I prefer to get materials like this from a specialist shop, rather than a general hardware store. A few words of informed advice from someone who has "been there and done that", can make all the difference. Here is a quote from Mapei tech sheet - "Mapegum WPS is a ready-to-use, solvent-free, single component, grey-coloured paste with a base of synthetic resins in water dispersion. Mapegum WPS has a thixotropic consistency which makes it easy to apply on horizontal, sloping and vertical surfaces. After rapid evaporation of the water content, Mapegum WPS forms a flexible membrane which is not sticky and which is strong enough to withstand light pedestrian traffic. It also forms an excellent surface which bonds perfectly to adhesives used for laying ceramics" The real break though with these type of products is indicated by the word "flexibility". On our first house (timber frame) I fixed the ceramic tiles in the bathroom and WC onto two layers of 6mm flat cement wall sheets. After about 3 years a crack appeared in each tiled wall, straight on the joint line of the cement sheets, which happened to be right in the middle of a tile. What a bummer! The tiles were set solid, but the expansion, contraction and other movements in the timber frame inevitably caused something to give. The movement was probably very small, but white shiny ceramic tiles being what they are, the cracks stuck out like dogs balls. The point I am making is that if I could have used one of the modern flexible waterproofing compounds , the cracking of those tiles would not have happened. The bathroom would still be acceptable. So, even if you don't have to comply with any waterproofing regulations, I highly recommend you waterproof your bathroom before fixing the ceramic tiles. Don't build it good enough for the next five years, until you sell the house! Build it to last. Waterproofing is cheap and easy to do. If you can use a paint roller and a brush you can do it. It is definitely messy, but the good thing is that it is water clean up. The minimum area to waterproof in a bathroom, is all the floor area that contains a floor waste and turn up 150 of the adjacent walls. All around the bath/shower area to a min. height of 1800. If no shower screen is fitted the min. width (from memory) should be 1400 from shower head. I did almost the whole room, to a height of 2000. (I purposely left the bit behind the cupboard, in case I ran out of material, and sure enough I had a small patch that didn't get covered). My tile height was 2100 (top of door frame). If I had been cheap and only done the exact area that the code requires I might have saved $30. Here's how I did it:-

It's a poor photo again, a wider angle would have been nice. Here is it ready for the inspection. Note the fan in the window, it is a cheap floor fan that I tied temporarily in place to suck out dust. Fixing The Hand Basin CupboardThe next job was to fix the cupboard that had been made at a local joinery shop.

Above is a shot of plinth for the cabinet, that has been laid in position. It has been packed up so that it is level. As is common with these plinths the joiner has made the back rail of the plinth shorter, and there bye higher off the floor than the front and cross members. this is to make it easier fitting. The faces that are seen, the front and left hand side have been laminated with the same colour as the cupboard itself. It is made out of plywood. At the front left hand edge I have stuck a chisel under it and adjusted it so that the the plinth is level each way, front to back and side to side. The maximum gap turned out to be about 16mm so I got a couple packers that measured 16mm and used them to scribe a pencil mark on the plinth that was 16mm up from the floor, all around the plinth. Incidentally the black "U" things that you can see are plastic packers that I got from a window and door manufacturer. They come in different thicknesses and make it very easy to fix door jambs etc. I used them because I had them handy, but a bit of something else 16mm thick would have worked just as well. I took the plinth outside and cut the waste off either my jigsaw and then finished off with my small buzzer. There was no need for extreme accuracy, as the tiles would cover any small gaps. I just had to sit solid and level.

Here I am just about to fix the drawer section of the cupboard. It sat nicely against the wall so I put a couple of 50 x 8mm Dynabolts through the top back rail (not seen here) to fix it to the wall. No fixing to the bottom or side, not needed. I didn't fix the plinth in any way either, it just sat there. The tiles would lock it into position.

The next section of cupboard needed two holes in the back for the hot and cold water pipes, and one in the floor for the floor waste. Instead of using my tape measure and getting a series of measurements, I used a staff. A staff can be any scrap of timber that's long enough. I am marking the distance of the water taps here from the side of the fixed section of cupboard. Then I turned the staff around and marked the height of them up from the top of the plinth. Then I used the other side of the staff to mark the hole size and the position of the floor waste. I cut the holes in the cabinet with hole saws that were a fair bit oversize, as to get them perfect is just not necessary, as cover flanges go on the waste and pipe fittings. I had to turn the water off and remove the elbow fittings to slip the cupboard in place.

Here's the cabinet dropped into position, with the pipe cap ends back in place and the bit of old sink waste stuck in temporarily to stop anything dropping down the hole. A couple of Dyna bolts to the wall, and a couple of screws to the already fixed drawer section fixed it solid I laid on the top and fixed it with screws from underneath.

Because the top was made out of a type of chipboard, (I was told it was fully water resistant etc etc.) I ran a bead of wet area silicone around the top. This was maybe a bit of overkill, as there would be another silicone joint going in when the tiles had been fixed. But it cost little to do, so why not?

OK here is the cabinet in use. Not it's intended use, but unavoidably new bench tops and the like get used before the job is completed. I have always made a practice of covering up new surfaces until the very last minute. Accidents can and do happen, if there's a bench, the other trades use it or stand on it, so instead of whingeing I always cover them up. A bit of cover ply, recycled carpet or in this case a bit of old 12mm MDF is good insurance. I stuck the MDF down to stop it sliding and possibly scratching the laminate. I used a couple of bits of that yellow stuff you can see, that is normally used to stick posters or notices up on walls. Back to bathroom renovation first page. Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship |

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||||||||||||||||||||