concrete expansion joints

In the previous page we talked about the reason and the placing of concrete expansion joints. Here I will be talking about the actual forms that they take.

The joint materials

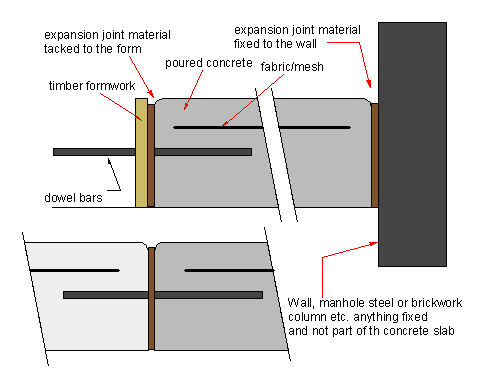

The means by which we stop the potentially destructive force in the concrete from damaging itself is to provide a wide joint at intervals that is sealed with some material that can expand and contract with the movement of the concrete, but at the same time is waterproof, long lasting and does not allow any extraneous material like sand or grit to enter the joint.

|

| concrete expansion joints - An isolation joint consisting of 12mm thick bitumen impregnated foam. In this instance it is fixed to the house walls with masonry nails. |

Where a concrete slab adjoins other building surfaces it is normal to provide isolation joints. These are usually the same material as the expansion joints.

- Concrete expansion joint material takes a few forms, but the most common in home construction work are the rolls of impregnated foam that come in various widths to suit slab thickness's.

- These are fixed to the formwork before the concrete is poured.

- Longer lasting expansion joints for more critical applications can be made with various gun grade or pourable Polyurethane or poly-sulphide type compounds. The more expensive an high-tech ones come in two pack kits.

- These compounds are said to have a high modulus of elasticity, that is they can stretch and shrink more than normal sealers. So look for the words "Hi-Mod" or similar on the cartons.

- The 12mm joint is formed in the concrete with something like softwood or polystyrene foam that is then removed when the concrete has set.

- The joint is then filled with the sealer compound.

- Don't waste your expensive sealant by sticking it into dirty or wet joints. Follow the manufacturer's instructions.

- This stuff is by it's very nature is sticky. If you are making joints in decorative concrete be careful not to smear adjoining surfaces.

- It may even be advisable to cover the joints with a board until the compound has truly cured to stop it being spread about.

By their nature concrete expansion joints do not have the reinforcing steel or mesh running through them. A break is always made in the rebar. This should be a minimum of 50 from the joint.

However it is common to have some sort of dowelled or keyed joint to provide some connection to each side of the joint to stop vertical movement. These are usually specified by the engineer.

Back to top

Traditional Concrete expansion joints.

|

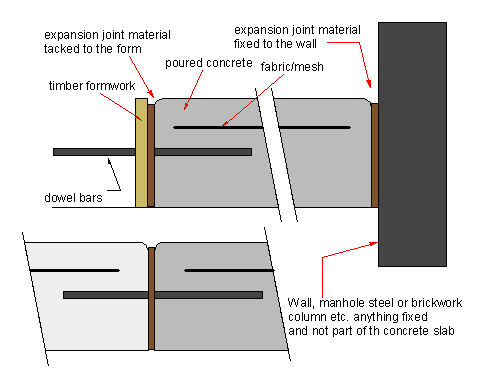

| Concrete expansion joints - A traditional expansion joint. The dowel bars are optional |

|

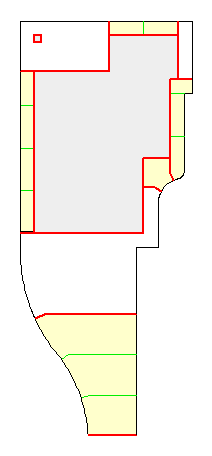

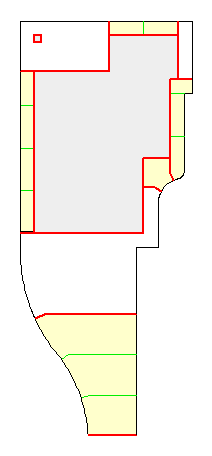

| Concrete expansion joints - This sketch shows a version of the one on a previous page. It shows the areas in yellow that could be poured in one day using traditional expansion joints. If modern joints were used this job could be completed in one day. |

The normal method of making a concrete expansion joint during most of the time that I have been doing them is sketched out above. We used timber almost exclusively for the joints, because it could easily be cut to length. The timber would be a thick board (35mm) or a made up shutter. It would pegs outside it to hold it in place.(not shown in sketch).

I have sketched in a version against a wall of an isolation joint, which is fairly standard. This could be impregnated foam which is simply left in place or any of the other methods mentioned above.

The dowels bars are fairly typical in thicker slabs. 130 and above for heavy duty driveways and larger buildings.

This old concrete expansion jointing method has a few pros and cons.

- The materials are readily available and cheap.

- No special tools or expertise needed to form them.

- By far the largest drawback to this old method and the main force for change has been the fact that on any one day it was not possible to finish even a small job. Alternate sections could be poured one day and the rest the next day when the joint timber had been stripped. See sketch on right.

- When dowels are used stripping the form is hard without breaking it.

- It ties up men and materials for a longer time.

- Hire charges increase for machines like concrete pumps.

- The tooled joints tend to look untidy. It takes skill and time with the edging tools.

- When pouring in sections a lot of work has to go into protecting the previous days edge from damage. Keeping the curing system intact and keeping the surface clean as men and materials are moved over and around it.

Back to top

New generation concrete expansion joints.

|

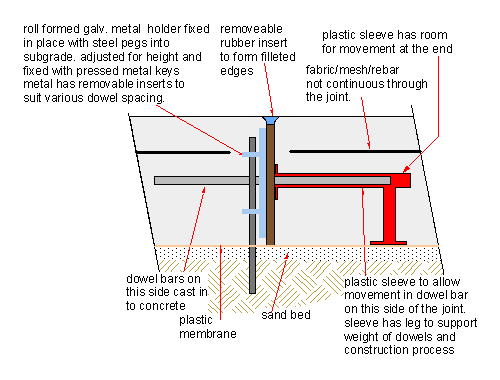

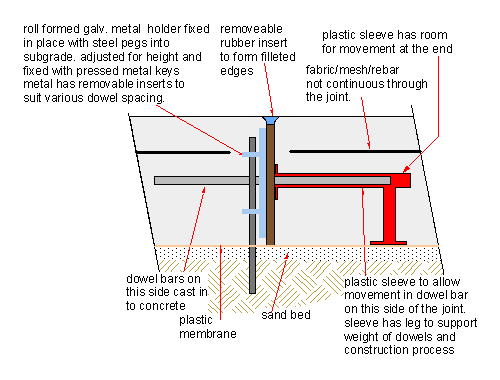

| Concrete expansion joints - A sketch of a modern expansion joint system that can be part of a continuous pour. |

- The benefit of being able to set up all subgrade, sand bed, plastic membrane, the joints, reinforcing steel at one time instead of in sections on different days is obvious.

- The joints themselves are quick and easy to fix straight and are easily adjusted for height with the pin and wedge system.

- The benefit of being able to do a longer concrete pour on any one day is enormous, with savings on labour and machine hire being only part of it.

- A lot of the modern systems have the remove able rubber sections to the top, giving a neat joint without any labour tooling the edges.

- The fact of being able to screed and later run rowelling machines over the joints makes for neater flatter joints.

- These proprietary concrete expansion joint systems are more expensive than a reusable timber. They get left in the concrete each time.

- They are not universal. Simply not available in some locations.

- The metal parts of the joints are protected to a certain extent by the design, and they are galvanised, but it would seem that within the slabs lifetime (30 years is common) there is a possibility of rust setting in and if left unattended then stains or worse could occur. Time will tell.

Back to top

A note on dowel bars.

Dowel bars in effect provide a reinforced connection between adjacent slabs. They cross the joint, yet they allow the separate concrete slabs to move independently in a horizontal direction and yet keep the slabs aligned vertically.

One side of the dowel bar is cast solid into the concrete and the other is allowed to move.

- In the traditional type of joint the bars were cast into the first section poured.

- Before the second one was poured the exposed ends of the bars were treated with some sort of bond breaker.

- In most cases it was simple grease or tape if the bars were plain R bars. (smooth).

- If the dowel bars where Y bars (deformed) a plastic sleeve was fitted with a bit of tape over the end.

- The newer systems have purpose made sleeves and in the sketch above I have drawn one system that has sup pots under the sleeves. This helps to keep the dowel bars in the correct position during the concrete work.

- Correct alignment of the bars is critical. To have some bars pointing up or sideways would obviously stop the concrete movement.

- One interesting new idea is the use of dowel plates. These are flat steel plates that take the place of bars. Much like the way that biscuit joiners replace dowels in joinery. The reason for the use of plates is said to be that the greater surface area of a flat plate is more effective than bars in controlling vertical movement.

It really depends on the type and use of the concrete slab if dowel bars are used or not. Any driveway that may experience heavy vehicular traffic should use them. That being said I am always in favour of more rather than less in residential cases also.

Any slab that requires the use of dowel bars is usually designed or approved by a structural engineer so that the details of the dowel joints are given along with the rest of the details.

Just as a guide:-

- Dowel bars are situated in the vertical centre of the slab.

- For a 100mm thick residential driveway (only light traffic) then 12mm bars, 500 long at 400 centres would be adequate

For large pavements with heavy traffic there a range of dowel baskets available which can hold various types of dowels, round square and plate in wire cages.