|

|||||||||||||||||||||||||||

Rafter cuts. The common rafter.

Here's a question from Charles A. who lives in Nashville. "I am building a 16 x 16 shed in my back yard. The roof pitch I would like to have is a 8/12. How do I get the measurement right in order to cut the board in the right place? I know how to cut the 8 at the top, that ties to the ridge but, I just can't figure out the measurement at the bottom or (notch cut). Thank you for any help you could give. I guess it is almost fifty years ago that I first came across rafter cuts. This would have been in a classroom setting at night school when I was an apprentice carpenter. The jump from seeing the various triangles and drawings on the blackboard, and then realising how all this information is applied in practise was a long time coming for me. The problem as I see it is that most of us who have gained a bit of knowledge, and I am including my trade school teachers here, tend to forget those first fumblings around in a dark haze, and write as though everyone has the same background as ourselves. So I will do this page solely on the humble common rafter and try to keep it as basic as I can. A pitch triangle

If you have read the previous pages, you will know that I am a believer in solving roofing problems by drawing it out, to a large enough size so that fairly accurate measurements can be got directly from the drawing. After the drawing is done then quite often I check my setting out with a pocket calculator.

The rafter length

Marking the rafter

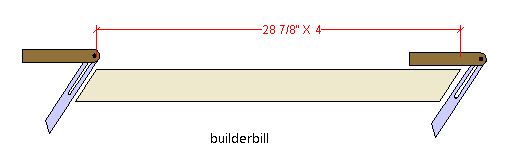

Above is a sketch of the rafter at it's simplest, a plumb cut to start, a measured distance of my size from the drawing times four, because the drawing is at a scale of 1:4.

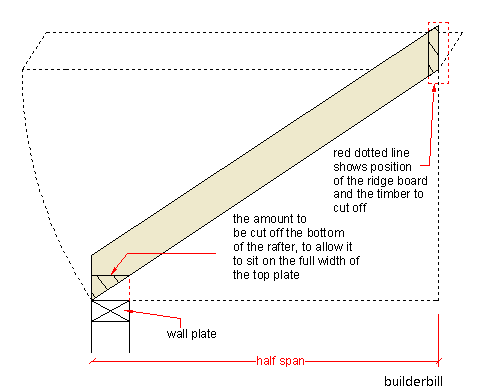

We mark out and cut our rafters on a couple of saw horses or stools, but above is a sketch of how this same rafter would look if it was rotated until the plumb cut is vertical and in it sits in the correct position.

Allowing for the ridge timber

Above is a sketch showing an easy way to allow for the ridge. Remember only half the thickness. The other rafter on the other side is shortened the same way. marking the foot cut

Above we see a similar way to mark out the level cut, measuring square off the plumb line. marking the birdsmouth cut.

here we show a way of marking the birdsmouth cut.

adding the eaves overhang.

In most cases there is an overhang at the eaves. An overhanging eaves is desirable in most cases because it helps to keep a lot of weather off the walls.

The finished rafter

Above is a sketch of the completed rafter with the birdsmouth and the eves added. This just about answers Charles' original question. my roof framing page will provide a bit more information for him. odd measurements.

That worked out quite well eh! The 8 ft. half span fit neatly with the 24" or 2 ft. base triangle that I had drawn. You would be right in thinking that in the real world things have a habit of being a bit more awkward than this example.

Not found it yet? Try this FAST SITE SEARCH or the whole web |

Hire Equipment  Furniture Fittings - Architectural Hardware - Electronic Locking Systems - Technical Hardware BuilderBill sponsorship Quick Illustrated Roofing Glossary Pages.Types of roofsRoof Features Roof Framing Roof Trusses Roof Coverings In Depth Roofing Articles

Adjustable bevels.Drawing on a piece of ply or other board like I show here, is ideal when using adjustable bevels to get your angles, whether for roofing or anything else. On a hip roof there are many more angles than the two shown here. Whatever way you find your angles, it is a good plan to mark them on the edge of a setting out board or sheet of ply as soon as you get them, and mark on them clearly what they are. Some of the angles can be quite similar, and you need to mark them clearly. This way you always have a handy reference to check against, if the bevel has been dropped, or you are changing it for some reason. If you only learn one thing from this page, it should be a variation of the old "measure twice and cut once" saying, and that is "double check that your bevel is correct" before cutting dozens of rafters. |

||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||

|

Please Note! The information on this site is offered as a guide only! When we are talking about areas where building regulations or safety regulations could exist,the information here could be wrong for your area. It could be out of date! Regulations breed faster than rabbits! You must check your own local conditions. Copyright © Bill Bradley 2007-2012. All rights reserved. |

|||||||||||||||||||||||||||